By Aaron Devitt, Co-Founder

In the wake of Black Friday's rush, maintaining optimal inventory levels throughout the holiday season becomes crucial for consumer electronics retailers. With recent studies showing that retailers lose an average of 4.1% of holiday revenue due to stockouts, smart inventory management isn't just good practice—it's essential for survival. Let's explore how retail intelligence can help you maintain the perfect balance between supply and demand.

The Cost of Poor Inventory Management

Recent retail data paints a clear picture:

- 34% of customers will shop at a competitor if a product is out of stock

- Overstock situations tie up an average of 18% of a retailer's working capital

- Poor inventory management leads to a 23% decrease in customer satisfaction during peak season

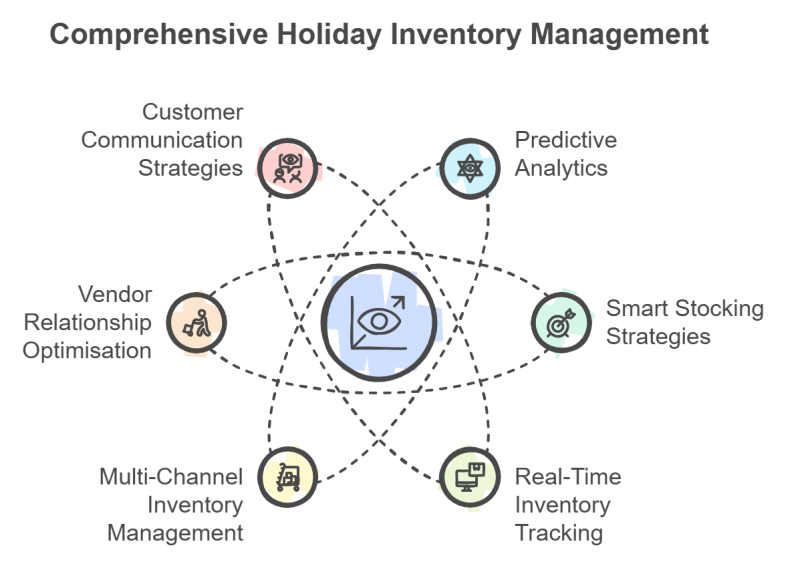

Every piece of your inventory management strategy works together like a well-oiled machine. From predictive analytics guiding your purchasing decisions to real-time tracking ensuring stock accuracy, each component plays a crucial role in preventing both stockouts and overstock situations. But the true power lies in how these elements integrate with your vendor relationships and ultimately serve your customers. Let's look at how these interconnected strategies create a robust framework for holiday season success.

1. Predictive Analytics: Your Crystal Ball for Holiday Demand

Historical Data Analysis

Transform past performance into future success:

- Review previous holiday season sales patterns

- Analyse year-over-year growth trends by product category

- Identify seasonal bestsellers and slow movers

Real-Time Demand Forecasting

Leverage current market indicators:

- Monitor online search trends for product categories

- Track competitor stock levels and pricing

- Analyse social media sentiment for upcoming products

2. Smart Stocking Strategies

Category-Specific Approaches

Different products require different strategies:

- High-margin items: Maintain higher stock levels

- Trending products: Implement dynamic reordering

- Slow movers: Minimize inventory investment

Buffer Stock Calculation

Use data to determine optimal safety stock:

- Calculate based on lead times

- Account for supplier reliability

- Factor in demand variability

3. Real-Time Inventory Tracking

Technology Integration

Implement systems for:

- RFID tracking

- Automated reordering

- Cross-location inventory visibility

- Real-time stock level updates

Early Warning Systems

Set up alerts for:

- Low stock levels

- Unusual demand spikes

- Supply chain disruptions

- Inventory discrepancies

4. Multi-Channel Inventory Management

Unified Stock Control

Maintain consistency across:

- Physical stores

- Online marketplace

- Mobile app

- Click-and-collect service

Channel-Specific Allocation

Optimize stock distribution based on:

- Channel-specific demand patterns

- Fulfilment capabilities

- Customer preferences

- Shipping considerations

5. Vendor Relationship Optimisation

Data-Driven Partnerships

Strengthen supplier relationships through:

- Shared sales forecasts

- Real-time inventory levels

- Performance metrics

- Collaborative planning

Fast-Track Replenishment

Establish protocols for:

- Rush orders

- Priority shipping

- Alternative sourcing

- Emergency stock transfers

6. Customer Communication Strategies

Stock Level Transparency

Implement systems to:

- Display real-time availability

- Offer pre-orders for popular items

- Provide estimated restock dates

- Enable stock notifications

Alternative Options

When facing stockouts:

- Suggest similar products

- Provide cross-store availability

- Enable waitlist registration

Understanding these strategies is one thing—implementing them before the holiday rush is another challenge entirely. A well-planned timeline ensures you can systematically deploy these solutions without disrupting your current operations. Here's how to strategically phase in these improvements to maximise their impact during the peak season.

Implementation Timeline

Pre-Holiday Season (Now)

- Review historical data

- Set up tracking systems

- Establish vendor agreements

- Train staff on new processes

During Peak Season

- Monitor real-time metrics

- Make dynamic adjustments

- Maintain communication channels

- Document learnings

Measuring Success

Track these KPIs:

- Stock turn rate

- Lost sales due to stockouts

- Inventory carrying costs

- Order fulfilment rate

- Customer satisfaction scores

While following this implementation timeline is crucial for immediate holiday success, the true value of these strategies extends far beyond the season. The data and insights you gather during this peak period become the foundation for year-round retail excellence.

Looking Forward

The holiday season is a marathon, not a sprint. By implementing these data-driven inventory management strategies, you're not just preventing stockouts—you're building a foundation for year-round retail excellence.

This article is part of our November series on "Maximising Holiday Sales in Consumer Electronics with Smart Retail Insights."

Get in touch today, or follow us on LinkedIn for our latest news.