By Emma Lester-Devitt, Managing Partner & Co-Founder

Our recent article, "Revolutionising Retail: AI Applications in Inventory Management and Demand Forecasting", introduced how artificial intelligence (AI) is transforming retail operations. Building on that foundation, today, we're diving deeper into the realm of AI-powered inventory management, offering you practical insights, key tips, and a look at some of the most effective tools in the market.

Should Retailers Adopt AI-enabled Supply Chain Management?

Before we delve into the specifics, let's remind ourselves why AI is such a game-changer in inventory management. According to a report by McKinsey,

“AI-enabled supply chain management can reduce forecasting errors by 20 to 50 percent and reduce lost sales due to product unavailability by up to 65 percent.”

These figures underscore the transformative potential of AI in retail operations.

Key Areas Where AI is Making a Difference

1. Demand Forecasting

AI excels at analysing vast amounts of data to predict future demand more accurately than traditional methods.

Tip: When implementing AI for demand forecasting, ensure you're feeding it a diverse range of data points. This should include not just historical sales data, but also external factors like weather patterns, local events, and even social media trends.

Example: UK-based fashion retailer ASOS implemented AI-driven demand forecasting and reduced excess stock by 30%, significantly improving their inventory turnover.

2. Real-Time Inventory Tracking

AI-powered systems can provide real-time visibility into stock levels across multiple locations, helping prevent stockouts and overstocking.

Tip: Integrate IoT devices like RFID tags and smart shelves with your AI system for even more accurate real-time tracking.

Tool spotlight: IBM's Sterling Inventory Visibility uses AI to provide real-time inventory information across all channels, helping retailers make informed decisions about stock allocation.

3. Automated Reordering

AI can automatically trigger reorders based on current stock levels, predicted demand, and even supplier lead times.

Tip: Start with a pilot programme for automated reordering on a small subset of products before rolling it out more widely. This allows you to fine-tune the system and build confidence in the process.

Example: Ocado, the UK-based online supermarket, uses AI to automate reordering for over 50,000 products, reducing waste and improving availability.

4. Dynamic Pricing

AI can adjust prices in real-time based on demand, competitor pricing, and other factors, helping to optimise sales and inventory levels.

Tip: Ensure your AI pricing model takes into account not just demand and competition, but also factors like product lifecycle and brand perception.

Tool spotlight: Blue Yonder's Price Optimization software uses AI to suggest optimal prices based on various factors, helping retailers balance profitability with competitiveness.

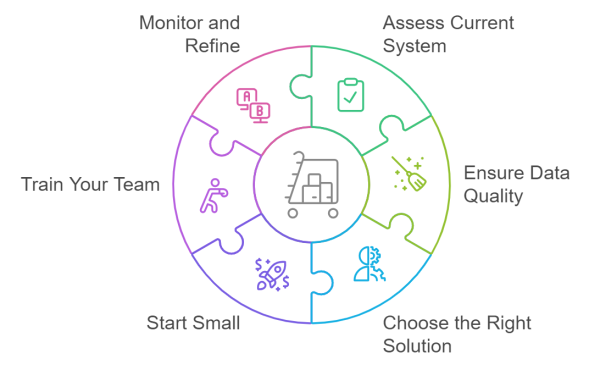

Implementing AI in Your Inventory Management: A Step-by-Step Guide

- Assess your current system: Before implementing AI, conduct a thorough audit of your current inventory management processes. Identify pain points and areas where AI could add the most value.

- Ensure data quality: AI systems are only as good as the data they're fed. Invest time in cleaning and organising your historical data.

- Choose the right solution: There's no one-size-fits-all AI solution. Consider factors like the size of your business, the complexity of your inventory, and your specific goals when choosing an AI tool.

- Start small: Begin with a pilot project in one area of your inventory management. This could be demand forecasting for a specific product category or automated reordering for fast-moving items.

- Train your team: Ensure your staff understands how to work with the AI system. This might involve partnering with your AI provider for training sessions.

- Monitor and refine: Continuously monitor the performance of your AI system and be prepared to make adjustments. AI systems learn and improve over time, so patience is key.

Case Study: Marks & Spencer's AI Inventory Management Success

Marks & Spencer, a major UK retailer, partnered with Microsoft to implement AI in their inventory management processes. The results were impressive:

- 30% reduction in store staff workload related to stock management

- Improved availability of fresh food items, leading to increased sales

- More accurate ordering, reducing food waste by up to 20%

Overcoming Challenges in AI Implementation

While the benefits of AI in inventory management are clear, implementation can come with challenges. Here are some common hurdles and how to overcome them:

- Data silos: Many retailers struggle with data spread across different systems.

Solution: Invest in data integration tools that can pull information from various sources into a central repository for your AI system. - Resistance to change: Staff may be hesitant to trust AI-driven decisions.

Solution: Involve key staff members in the implementation process and provide comprehensive training. - Cost concerns: AI implementation can require significant upfront investment.

Solution: Start with smaller, high-impact projects to demonstrate ROI before scaling up.

The Future of AI in Inventory Management

As AI technology continues to evolve, we can expect even more sophisticated inventory management solutions. Some areas to watch include:

- Predictive maintenance: AI will not only manage stock levels but also predict when equipment used in inventory management (like forklifts or conveyor belts) needs maintenance, reducing downtime.

- Enhanced visual recognition: Advanced computer vision will allow for more accurate and efficient stock counting and identification.

- Blockchain integration: Combining AI with blockchain technology could provide unprecedented transparency and traceability in supply chains.

Embracing the AI-Powered Inventory Revolution

AI-powered inventory management is no longer a futuristic concept—it's a present-day reality that's providing significant competitive advantages to retailers who embrace it. By leveraging AI for demand forecasting, real-time tracking, automated reordering, and dynamic pricing, businesses can optimise their inventory levels, reduce costs, and improve customer satisfaction.

As you embark on your AI implementation journey, remember that success doesn't happen overnight. Start small, focus on data quality, and be prepared to refine your approach as you go. With patience and persistence, AI can transform your inventory management from a operational headache into a strategic asset.

Are you ready to take your inventory management to the next level with AI? The future of retail is here—and it's smarter than ever.

Get in touch today, or follow us on LinkedIn for our latest news.